- 1D CHARGE EXCHANGE, PERFORMANCE- AND ACOUSTIC CALCULATION

- 3D THERMAL HEADLIGHT SIMULATION

- 3D CFD SIMULATION

- MULTIBODY SIMULATION (MKS) AND FINITE-ELEMENT-METHOD (FEM)

- METHODOLOGY DEVELOPMENT

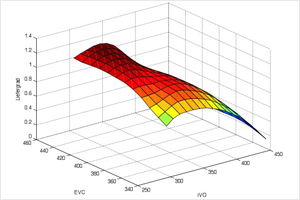

Engine process simulation

Wave Engineering assists you with the performance and engine optimization and by increasing the volumetric efficiency and with the development of new power units through thermal use.

With the use of 1D simulation, we can perform highly-efficient calculations. Our simulations require a low modeling effort and short computation times and thus provide quick results. We focus on parametric studies and design of experiments (DOE) and use the software tools of leading software developers in 1D simulation: Wave of Ricardo and GT-Power of Gamma Technologies.

1D calculation of the oulet sound level acoustics of the intake and exhaust systems

The design of a system can be changed through the simulation at an early stage, that way each vehicle will have a specific sound, e.g., sporty, meaty sound or comfortable, discreet sound. In addition, we can calculate the weight, the noise level and the backpressure of the exhaust system accurately and thus help to reduce the CO2 emissions and fuel consumption

Coupling of 1D gas dynamics analysis and 3D CFD

For the design of intake and exhaust systems, we use coupled 1D/3D solver to connect the accuracy of the 3D simulation with the speed of the 1D simulation.

38440 Wolfsburg

Germany

Fon: +49 5361 1810180

At an early stage of development it is possible to graphically represent the heat distribution within a headlight. That way failure of the headlight can be prevented during the early stage of the design development. In addition, the thermal simulation allows for a selection of cheaper materials, thus leading to lower production costs.

With the help of the 3D simulation, Wave Engineering can represent possible thermal problem areas in an early development phase. This enables our customers to optimize the selection of materials early and forgo manual measurements and the construction of prototypes. This will save you money and time. Furthermore possible tool changes can be avoided during production.

more information38440 Wolfsburg

Germany

Fon: +49 5361 1810180

The earlier the properties of the product are known in the development process, the fewer changes are required later on for measuring and test campaigns. The detailed simulation of the physical properties can save you a lot of money.

Wave Engineering provides solutions in the field of flow simulation and thermal protection and gives suggestions to optimise the flow geometry, solving thermal and flow problems after analysing the fluid flow and heat transfer in the complex systems. We offer 3D flow simulation and coupled simulations, e.g. flow and radiation simulation, for closer examination of heat transfer problems. We can perform your simulations with a large range of commercial software tools, for example, Vectis, Fluent, or Radtherm StarCCM+.

In addition, we can offer simulation processes based on OpenSource software such as OpenFoam.

38440 Wolfsburg

Germany

Fon: +49 5361 1810180

These technical calculations are very important for development and allow making concept decisions at an early stage. Wave Engineering also demonstrates great expertise in the field of multi-body simulation. We support our customers with the calculation of complete vehicle models for determining the component movements.

This simulation provides many advantages, especially for the space assessment in the earlier phases of the product development process. This way, we can help to shorten development times and reduce costs. To avoid collisions of individual components in the engine compartment, our customers place great value on these calculations, which are relevant for the development process.

more information38440 Wolfsburg

Germany

Fon: +49 5361 1810180

In addition to our large portfolio in the CFD simulation, we have extensive experience in the development of new simulation processes. We offer expert knowledge in the field of interface programming of co-simulations and the coupling of software, e.g., 3D CFD and FEM simulation of fluid-structure interaction, and 3D CFD and radiation solvers for the calculation of heat transfer processes. Just contact us. Together we will find a solution that is individually tailored to your needs.

more information38440 Wolfsburg

Germany

Fon: +49 5361 1810180